The dye industry has recognized the growing need for green and sustainable practices to prioritize environmental protection. As wastewater treatment becomes a key component of the industry, the application of electrocatalytic oxidation technology has emerged as a promising solution.

In recent years, the global emphasis on green manufacturing and cleaner production has continued to increase. The environmental impact of every industry is under intense scrutiny, and the dye industry is no exception. The dye manufacturing process generates large amounts of wastewater, which often contains pollutants that can harm ecosystems and human health if not treated properly.

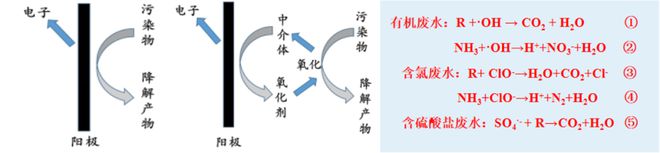

This has resulted in an urgent need for effective wastewater treatment methods. Electrocatalytic oxidation processes, including direct oxidation and indirect oxidation technologies, have attracted attention as a promising solution. The technology uses electrochemical reactions to remove contaminants from wastewater, making it a sustainable and efficient method for the dye industry.

The application of electrocatalytic oxidation technology in the dye industry has various advantages. First, it is a sustainable solution that is in line with the industry’s green manufacturing goals. Helps minimize the environmental footprint of the dye industry and promotes cleaner production practices by effectively removing contaminants from wastewater.

Secondly, electrocatalytic oxidation technology provides a cost-effective method for treating dye wastewater. The technology requires fewer chemicals and uses less energy than traditional treatment methods such as chemical coagulation or biological treatment. This means lower operating costs for dye manufacturers, making it an attractive option for implementing sustainable wastewater treatment practices.

Furthermore, the electrocatalytic oxidation process offers versatility in treating various contaminants in dye wastewater. The technology effectively removes a wide range of contaminants, from organic dyes to heavy metals, ensuring the treated water complies with strict environmental regulations.

Our factory is updating the equipment of dyes wastewater. Our factory production capicity of sulphur black is 600tons per month. We supply various strength according to customers’ requirement, 200%.220%.240%. Our sulphur black has shiny appearance. We have bluish and reddish shade. We can offer you free sample to test.

Post time: Oct-20-2023